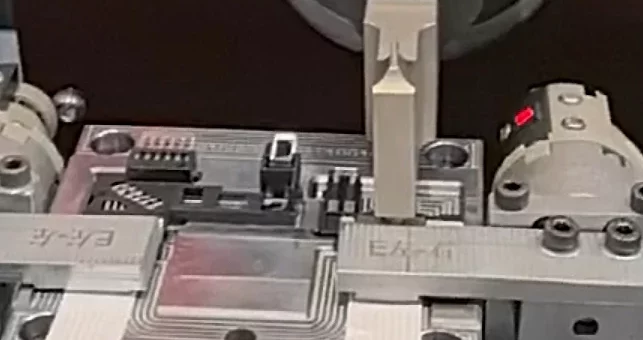

The challenge of FPC is its tiny thickness to be welded, which is easy damaged if welding even if little welding over on one hand while on the other hand the welding will be easily loose if welding is not enough, requests high precision control in ultrasonic output. With MP Sonic stable ultrasonic system in precision controlled by super-high computing ability and computing speed, MSP-JS2032-F realizes stable qualified welding to FPC in stability.

Flexible Circuit Ultrasonic Welding System

FPC Welding by MP Sonic Metal Ultrasonic Welding System

]]>

I. Feature:

1. Anti-resonance ultrasonic system for strong power output and perfect welding result with high loading;

2. Mechanical adjustment for welding depth meeting different welding requirement;

3. Welding mode can be time mode or energy mode according to requirement;

4. Automatic intime frequency tuning to match welding tooling working manner, ensuring machine stable operation performance;

5. Impedance analysis function design to test and analysis welding tooling;

6. Ultrasonic generator applies MP Sonic intelligent operation system with multiple function including: Welding Parameter Formula System, Welding Process Graphic Supervision System, Welding History Checking System; Alarm History Checking System, Horn Test System, USB Downloading System for welding data, etc.

7. Multiple protection system is designed for equipment safety including over loading protection, over voltage protection; impedance threshold protection, wrong frequency protection, etc.

II. Optional Feature:

1.???????Welding depth mode system;

2.???????MES network system and I-cloud service system.

III. Specification:

1. Model Code: MSP-JS4010;

2. Electric Supply: 220V, 1P, AC, 50/60Hz;

3. Air Supply: 0.5~0.8MPa;

4. Ultrasonic Specification: 40KHz, 1000W;

5. Ultrasonic Output Peak Value: max to 1200W;

6. Measurement: Machine-L440*W270*H330 (mm), Generator-L36*W46*H24 (mm)

]]>Ultrasonic welding machines can apply both analogue ultrasonic generator system and IGBT (digital) ultrasonic generator system basing on what customers like.

Ultrasonic Welders?applies the ultrasonic systems to excite resonance of material molecules of parts to be welded and generate heating to melt the material at welding area, after which stop ultrasonic working and keep parts hold under high pressure until material cold to become re-solidification.

Normally, ultrasonic welder for plastic welding can be in?15KHz, 20KHz, 28KHz, 30KHz, 35KHz?and?40KHz. The power can be from?300W?to?5600W. But different ultrasonic frequency, the peak value of ultrasonic power output is different.

For metal welding, normally it is 20KHz 3000W~6000W or 30/35KHz max to 1200W.

When you select a ultrasonic welder, you need to consider your requirement in detail as below factors:

1. Parts measurement;

2. Parts geometric design;

3. Parts material;

- Welding quality standard: A. welding strength; B.air-tightness; C. welding control precision; D. Outlook after welding.

- Feature:

- IGBT ultrasonic system applied with real time frequency auto tuning;

- Two welding control mode: time mode & energy mode;

- Adjustable ultrasonic amplitude control in 10~100%, by 1%;

- Ultrasonic output two phase control is available;

- Welding record for production statistics;

- Welding result judgement assists the quality management;

- Multiple protection: overload protection, high voltage protection, threshold valve protection, etc;

- Impedance analysis function to ultrasonic horn;

- Micro computer controlled with 485 communication, 4-cores-CUP achieves fast reaction speed in accuracy;

- Four linear ways in high precision applied achieves repeat motion in high precision;

- Micro adjustment design for welding depth control in precision;

- Ultrasonic welding head in strong and precision design to ensure machine stability and accuracy;

- Air blower is equipped with machine for fast cooling after welding.

- Optional Feature:

Dept control mode by linear sensor for advanced welding control.

III. Benefit:

- Intelligent ultrasonic system;

- Precision machine design;

- Stable machine fabricated;

- Takes up small space;

- Perfect welding result concerned to others welding procedure.

III. Specification:

- Model: JS2032;

- Power Source: 220V, 1P, AC, 50/60Hz;

- Air Source: 0.6~0.8MPa;

- Ultrasonic Frequency: 20KHz;

- Ultrasonic Power Output: max to 3200W;

- Air: 0.6~0.8MPa;

- Weight: Machine is 75, generator is 8;

- Dimension: 340*620*430 (mm);

- Cylinder: ?100*25mm.

5. The deformation of part moulding.

Also you need to consider your demand of machine function as below according to your actual need:

1. Manual tuning or automatic tuning;

2. Welding mode: A. time mode; B. energy mode; C. depth control mode; D. external trigger mode;

3. Amplitude control;

4. System protection;

5. QC management;

6. Frequency in-time self search or not;

7. Self protection.

]]>Machine is?designed in precision control, depth control mode is available as an?optional feature.

Why apply ultrasonic to splice?

- No heating to metal wire, no melting to material, no change to the characters of material;

- No extra resistance to cable after splicing by ultrasonic;

- Efficiency in operation;

- No consumables requestes, economical production.

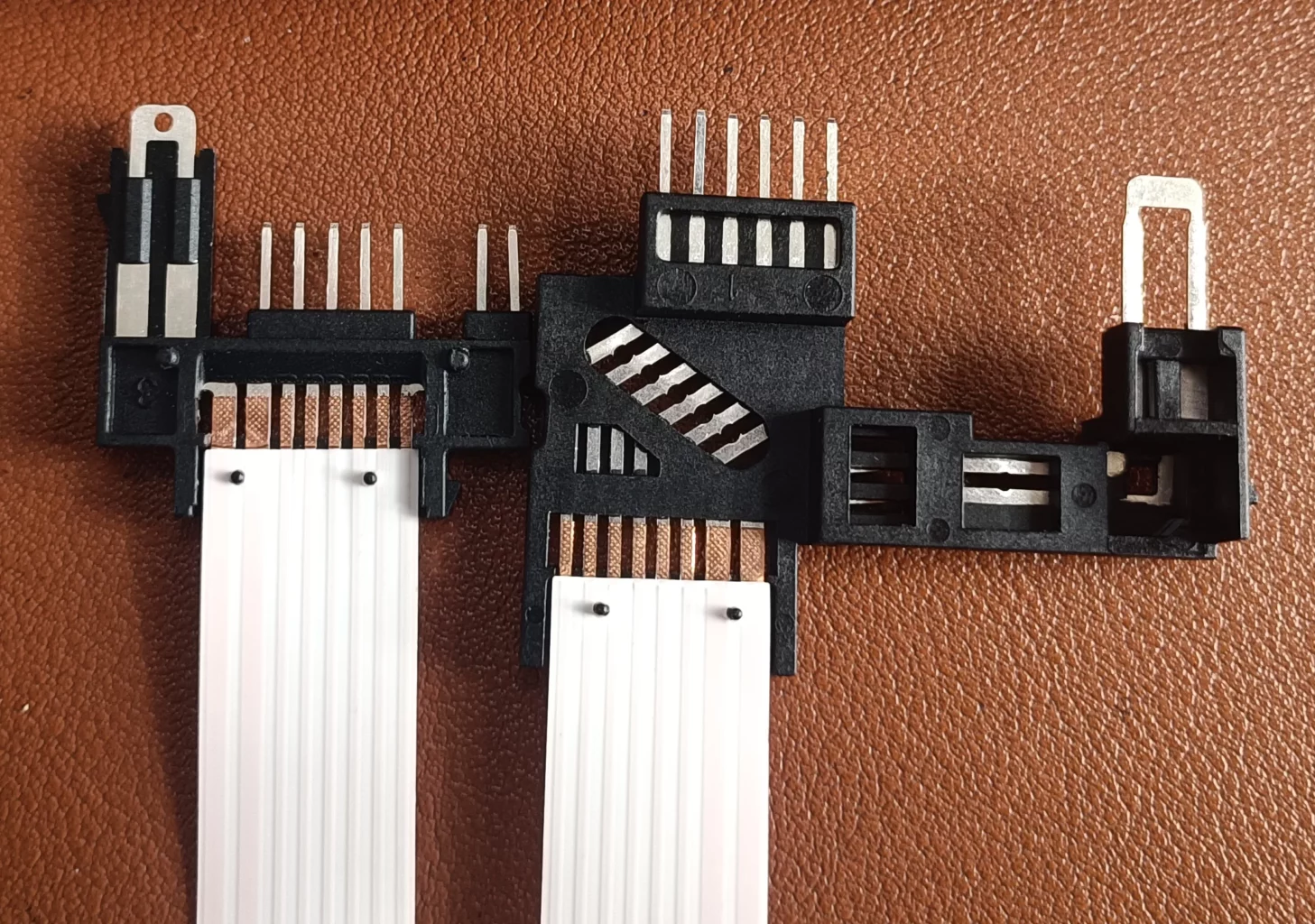

I. Feature:

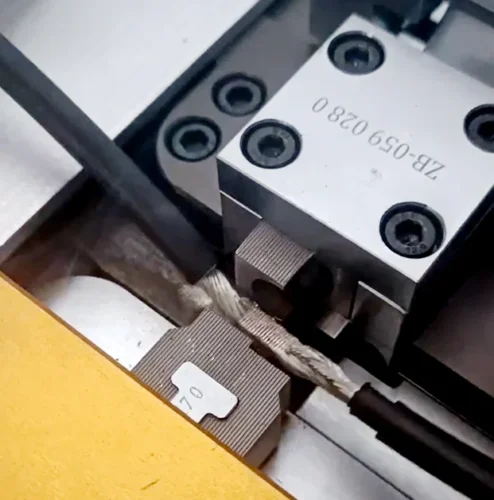

1) Strong ultrasonic power output, can be applied for the splicing of metal wire max to 80mm2;

2) Precision control with accurate?depth adjustment;

3) Ultrasonic system is designed with amplitude control, multiple self protection system, different mode control system, welding steps control, etc, fit for different and complex welding condition;

II. Benefit:

1. Intelligent ultrasonic system control;

2. MP Sonic Korea standard Anti-resonance system design ensure high power output under loading;

3. Machine precision design;

4. Stable machine fabricated;

5. Small size takes up small space;

6. Excellent performance for metal cable welding.

III. Specification:

1) Power Source: 220V, 1P, AC, 50/60Hz;

2) Pneumatic Source: 0.5~0.8MPa;

3) Ultrasonic System: 20KHz, 3200W;

4) Dimension: 568*190*185 (mm).

IV.Critical Sares:

]]>

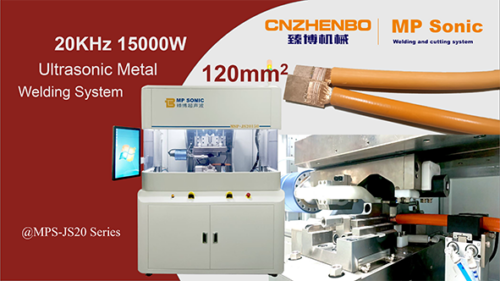

MSP-JS20150, with 20KHz ultrasonic system in power output max to 15KW, which achieves the welding capacity to copper cable in size max to 120mm2. Machine is designed mostly for the welding of high-voltage cable. Machine applies industrial PC panel to operate and set machine with MP Sonic specially developed ultrasonic control & management operation system, providing the solution to the complex requirement and demand of application in metal welding.

Benifit

1. MP Sonic 15KW ultrasonic metal welding system, high welding ability in stable performance;

2. Machine manufacturing in high precision with multiple manufacturing process procedure from high glass material, ensure machine duration in stability and precision;

3. Welding motion is Linear way guided in high precision (precision as high as 0.01mm);

4. Industrial Panel PC is equipped with machine for operation control, MP Sonic intelligent operation system for easy operation, meeting high requirement in management-quality management, production management, equipment management, etc.

Read Specification

See Video

]]>