MP Sonic designs and builds customized station for customer to cut material on automotive bumper by laser and to weld elements by ultrasonic. Machine normally designed with double stations and process cutting by robotic system. Different bumper can be produced by machine station through tooling changing-over and programming.

- Laser cutting for smooth cutting;

- 6-axies robotic motion controlled with double stations for short cycle time;

- Programmable for different parts process;

- Ultrasonic system applied for welding;

- Camera video supervise inside machine intime state with memory recode;

- Base fixture changeover system for different parts process;

- Dedust system equipped to remove smoke cased during laser cutting;

- Safety protection all-around for human and equipment.

Machine can be applied for ultrsonic cutting also through changing horn into ultrasonic cutting knife.

I. Features:

1. Programmable process procedure, can be applied to produce door trim panel in different design through tooling changing-over;

2. Advanced ultrasonic system applied, welding process cycle time min to 2.6S/point;

3. Intelligent control for production and quality management;

4. I-Cloud system for remote service fast machine service in low cost.

II. Basic Technical:

1. Power Source: 380V, 3P, AC, 50/60Hz;

2. Air Source: 0.5~0.8MPa;

3. Ultrasonic System: 35KHz, 1200W, MP Sonic Brand.

Note: Because this kind of machinery equipment is special application purpose, which should be designed according to detail requirment, thus before offer, we need your parts data and requirement in detail to make technical proposal.

]]>Through change-over ultrasonic horn and base fixtures, machine can be applied for ultrasonic welding also by programmable action.

Machine can be applied for?automotive industrial production, such as the assembly of dashboard, bumper, door trial panel, spoiler, etc.

Machine space is designed?considering?the transport by container, transport is easy.

?

I. Features:

1. Programmable action for multiple application;

2. MP Sonic features ultrasonic system with advanced control;

3. Mex system designed for remote operation, control, supervision and service;

4. Vacuum is designed for base fixture action;

5. Multiple pneumatic solenoid valves for base jig fixtures action;

6. MP Sonic intelligent operation system for multiple function in operation.

?

II. Main Technical Parameters:

1. Power source: 220V, 1P, AC, 50/60Hz;

2. Air Source: 0.6Mpa;

3. Machine Measurement: L2280*D3014*H2225 (mm);

4. Ration Power: 4.5KW.

]]>

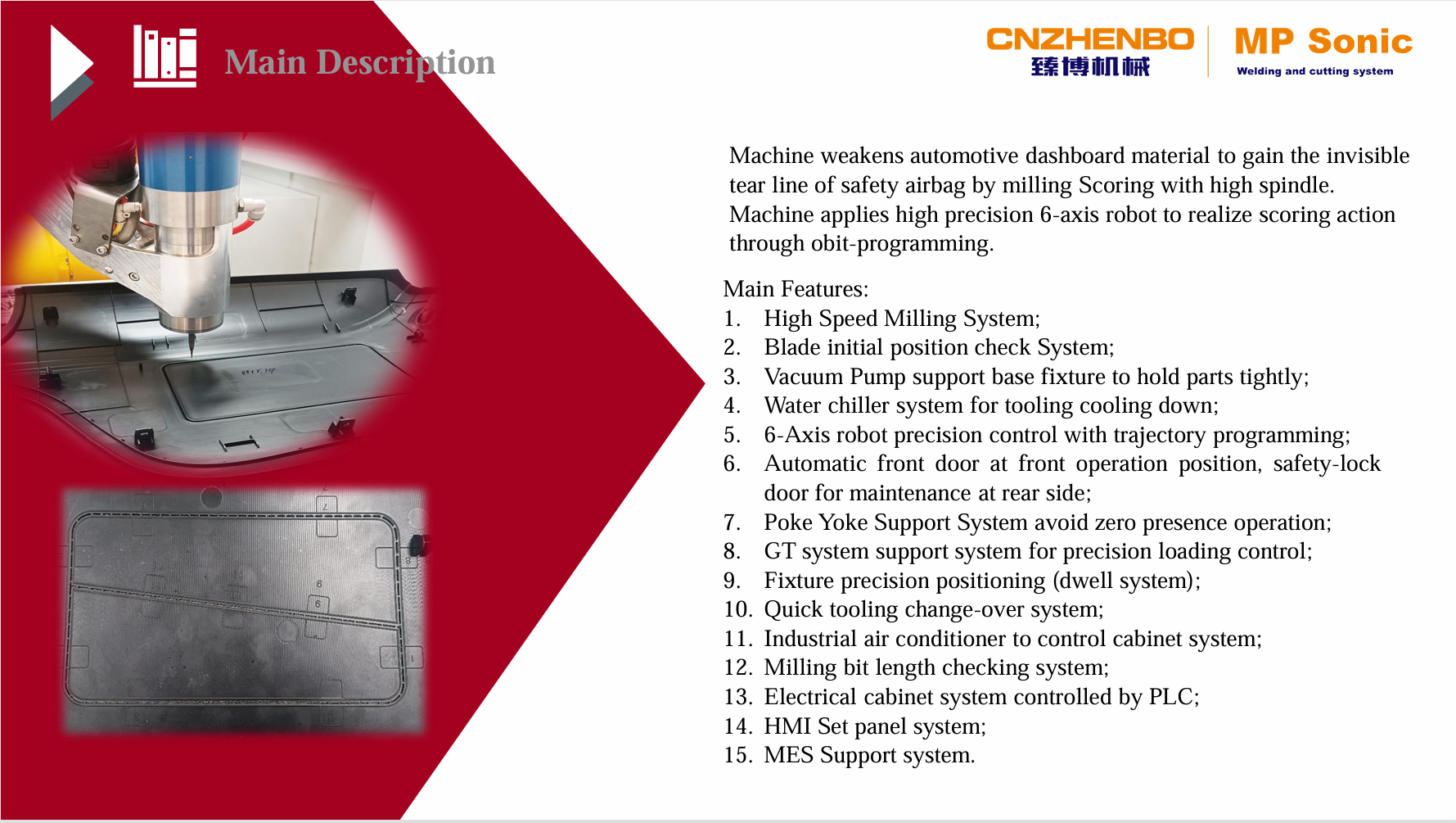

Milling scoring for PAB tearline,? ensuring the successfully explosion out of airbag by the designed tear line, is the last guarantees the life of passenger.

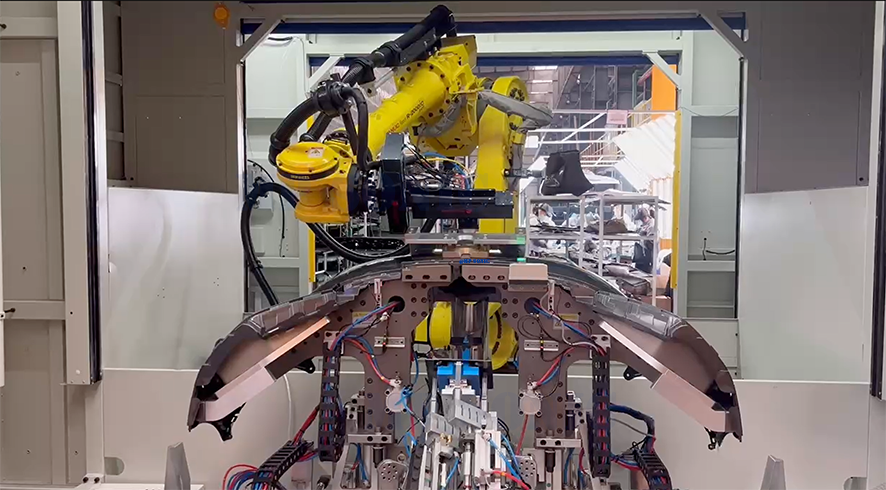

Machine weakens automotive dashboard material to gain the invisible tear line of safety airbag by milling Scoring with high spindle. Machine applies high precision 6-axis robot to realize scoring action through obit-programming.

Main Features:

1.High Speed Milling System;

2.Blade initial position check System;

3.Vacuum Pump support base fixture to hold parts tightly;

4.Water chiller system for tooling cooling down;

5.6-Axis robot precision control with trajectory programming;

6.Automatic front door at front operation position, safety-lock door for maintenance at rear side;

7.Poke Yoke Support System avoid zero presence operation;

8.GT system support system for precision loading control;

9.Fixture precision positioning (dwell system);

10.Quick tooling change-over system;

11.Industrial air conditioner to control cabinet system;

12.Milling bit length checking system;

13.Electrical cabinet system controlled by PLC;

14.HMI Set panel system;

15.MES Support system.

- The working table is designed with quick tool change, which takes about 5 minutes when tool change.

- The spindle is cooled by water circulated from chiller. The water temperature and flow rate are monitored by system. In case they are out of limit, the system will send alarm and the frequency convertor will stop the spindle. The current and rotation rate of spindle are controlled by frequency convertor. In case of overcurrent or abnormal rotation rate, the spindle will be stopped immediately. Chiller remains water temperature at 20 degree C. In case temperature is out of range, spindle will be stopped via switch valve.

- Service back door is equipped with auto lock system to insure safety requirement

- The machine contains fixture recognition function, the robot can automatically find corrected program.

- The machine is compatible to two cavity fixture of LHD & RHD.

- The machine will automatically measure milling bit length and also make compensation for robot arm change due to expanding with heat & Contracting with cold, in order to make remaining thickness stability.

- The machine has sensor to detect fixture position correctly.

- Only when the part is accurately positioned on fixture, the PLC will inform robot to start milling. Robot will not start in case vacuity does not reach set value. During weakening, in case of sudden vacuum leakage or loss, machine will automatically punch hole on part for NOK.

- The Machine is applicable to the fixture with movable OK punch design, for easy load & unload.

- The Machine has Poke Yoke function to avoid product being weakened 2nd time.

- Option: with basic traceability function, including one gun scanner and related program.

? ? ?Download Machine Detail

See Video

See Video